Since the world's first transistor was born in bell LABS in 1947, humans have entered the era of integrated circuits. According to Moore's law, the density of IC integrated circuit is higher and the size requirement is smaller. The manufacturing process of IC is developing towards miniaturization.

While, when junction temperature (Tj) of the chips goes up every 10 ℃, the service life of the device would be reduced by half, and the failure rate would be increased by twice. Therefore, with these problems existed, the designers need to work out a solution to solve the thermal failure, and developers also have to figure out a solution to improve the cooling system.

The chips are very important components of the switches, and thermal design and heat treatment performance would influence the stability and reliability of switches. The following is a brief introduction to the thermal design of electronic components.

The main idea of heat treatment of chip

1. Selection.

In the manual of thermal performance, it provides specifications of TA, TJ, ΘJC, ΘJA, PD, RDS, & I etc, with combination of TJ calculation formula (TJ=TC + (ΘJC*Pd)), through which users can get most suitable device.

Under the same conditions, there is the priority selection to the chip with heat dissipation sink on the bottom and metal packaging on the surface.

Except for choosing excellent chip, UTEPO combined with own characteristics to make the following strict regulations on the temperature derating of some key chips to ensure product quality and reliability.

2. Optimize the partial cooling environment

There are three ways of heat dissipation, including heat conduction, heat convection and heat radiation.

According to the structure of natural cooling way and occlusive operation environment, UTEPO has designed the switches with heat conduction and heat convection way, and auxiliary heat radiation way, which helps the cooling in full aspects and ensure the long term reliable operation.

3. Selection of heat conducting materials and technology

It is helpful to add heat conduction material to the surface of the chip for a better heat dissipation.There are many kinds of conducting materials, including metals, non-metals, liquids, gases and so on. Generally speaking, the thermal conductivity of metals is better than that of non-metals.

Most of the UTEPO switches are made of metal with high thermal conductivity, such as aluminum alloy and copper. In order to increase the heat transfer area of the chip, a multi-fin heat sink is also adopted. Meanwhile, nano-spraying technology is adopted to enhance the heat radiation transfer performance and improve the overall heat dissipation performance of the switches.

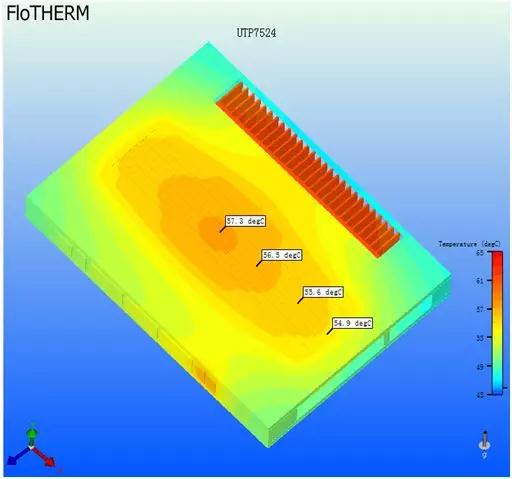

UTP7524GE-POE-P, UTEPO high power fanless PoE switch, is desiged with excellent heat dissipation solution. Equipped with high efficiency heat sink, there are heat dissipation holes all around the housing. Thus, it ensures the normal cooling performance without fan, and also the reliable operation under high temperature of 55 ℃.

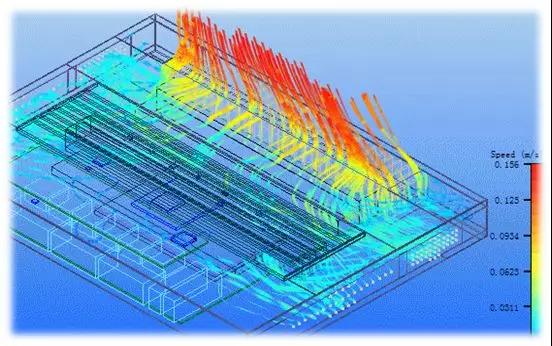

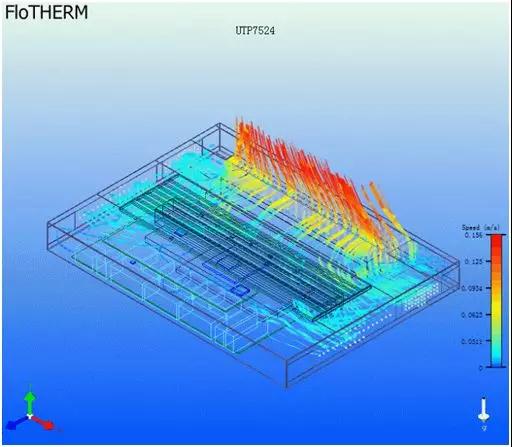

Natural Convection 3D View

Thermal Simulation Temperature Screenshot

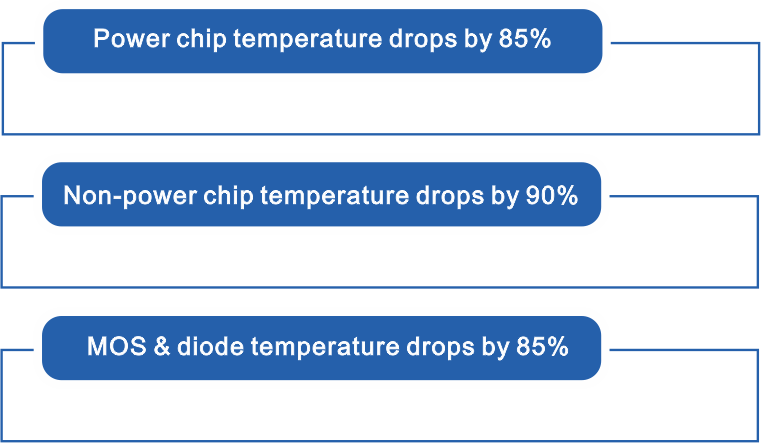

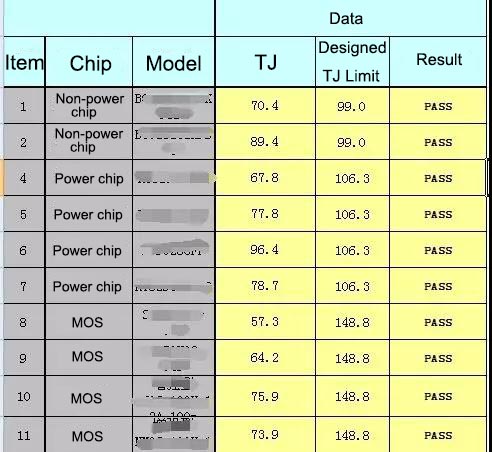

In order to ensure the stability and reliability of products, UTEPO would take a strict temperature rise test on the switches before they are released to verify whether the temperature of components meets the requirements.

It can be seen from the test results, the temperature of UTP7524GE-POE-P components is within the scope of the provision, and hold the allowance for the 10% to 15%, which can guarantee the stable operation of switches in the harsh environment.

UTP7524GE-POE-P Testing Tablet

Application of fanless switches

In the past, the heat dissipation of the switch was mainly solved by the built-in fan. On the one hand, the equipment was noisy during operation, which was not suitable for places with high static requirements. On the other hand, it will generate a lot of power consumption with operation of fan, which is not conducive to energy conservation and environmental protection, and also affects the overall stability and reliability of the equipment. While UTEPO fanless switches can keep stable operation without above problems, Moreover, UTP7524GE-PoE-P is the industry's first high-power fan-free switch, with 350W PoE power budget output for more cameras.

+86-755-83898016-863

+86-1501-2669-765

[email protected]

Note: To speed up our service to you, please make sure the field with " * " mark is filled before you click on "Submit" button, Thank you!